How Christmas tree netting is made – from monofilament yarn to a finished sleeve

How Christmas tree netting is made – from monofilament yarn to a finished sleeve

For most end customers, Christmas tree netting is just a white or green sleeve

that the tree passes through before leaving the sales area. For companies handling wholesale sales

and packing of Christmas trees, it is a key element of an efficient season. Behind the simple look of the net

there is technology, precise machines and the experience of a professional

monofilament netting manufacturer.

In this article we show how a single monofilament yarn becomes a finished

Christmas tree net that can withstand an intensive season, long transport routes

and multiple loading operations.

Monofilament – the heart of Christmas tree netting

The quality of the net starts with the type of yarn used. High-grade

monofilament yarns are selected to ensure:

- high resistance to tearing,

- stable shape during operation,

- consistent diameter parameters,

- good performance in both manual and automatic packing.

Thanks to this, monofilament Christmas tree netting can handle thousands of packed trees

in a single season without unpleasant surprises in the yard or warehouse.

The production process of Christmas tree netting

From the point of view of companies selling Christmas trees, only the finished roll on the stand is visible.

In reality, the path from plastic granulate to the final net consists of several important stages.

Below is a simplified description of how Christmas tree nets are manufactured.

1. Extrusion of monofilament yarn

The first stage is the production of the yarn itself. Plastic granulate is heated, melted and pushed

through special nozzles. This creates thin but very strong monofilament yarns

with a precisely defined diameter.

Controlling this stage is crucial, because it determines the later strength of the

Christmas tree netting, its elasticity and resistance to weather conditions.

2. Winding and stabilisation of the yarn

The finished yarns are then wound onto spools and stabilised so that they retain their parameters

in further processing. At this point, the uniformity of the diameter, the colour and the behaviour

of the yarn under tension are checked.

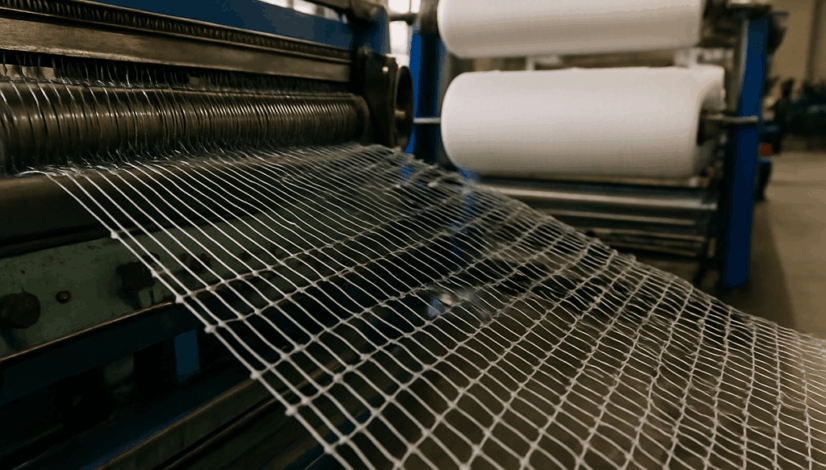

3. Knitting the Christmas tree net

The next step is creating the structure of the net. Special machines connect individual yarns into

a pattern of meshes, forming the characteristic structure of Christmas tree netting.

This is where the final strength and elasticity of the product are built.

Depending on the intended use, it is possible to produce Christmas tree nets

with different parameters – from models ideal for manual packing to nets designed mainly

for automatic packing lines.

4. Forming the sleeve and preparing the rolls

The finished mesh structure is formed into a sleeve with the required diameter and then wound onto rolls.

This is the product that B2B customers know – convenient to place on a cone or packing machine.

At this stage, the length of the rolls, the evenness of winding and compliance with the ordered parameters

are controlled. Thanks to this, a company packing Christmas trees knows exactly how many trees can be packed

with a single roll.

Quality control – why it matters for business customers

From the perspective of sellers and packing companies, the most important thing is that the net

“just works”. That is why every stage of production is subject to quality control. Among other things, the following are checked:

- resistance to stretching and tearing,

- size and consistency of the meshes,

- colour stability,

- behaviour of the net when used on packing machines.

As a result, companies ordering Christmas tree netting receive a product that behaves

the same from season to season. This makes it easier to plan operations and avoid unnecessary downtime.

Why the production technology also matters for the end customer

The quality of the net influences not only the comfort of packing, but also the final impression

for the person buying the tree. A well-selected Christmas tree net:

- better protects branches from damage,

- helps the tree keep its shape after unpacking,

- makes transport and carrying easier,

- builds a sense of professional service at the point of sale.

In times when customers compare offers and readily share opinions, reliable

Christmas tree netting becomes a quiet but important ally for companies

that want to stand out with the quality of their service.

Summary – a net is more than “just a white sleeve”

From plastic granulate, through monofilament yarn, to the finished roll on the packing stand –

the production of Christmas tree netting is a complex process where experience

and technology really matter. By choosing high-quality monofilament nets, companies involved in

packing and selling Christmas trees invest in a product that directly translates into easier work,

fewer damaged trees and a better experience for the end customer.